Combined insulation and underfloor heating system for timber floors

- Fully foiled layer maximises heat output

- High grade insulation increases energy efficiency

- Faster to install than traditional insulation panels thanks to multi-direction channels

- Completely silent on warm up and cool down

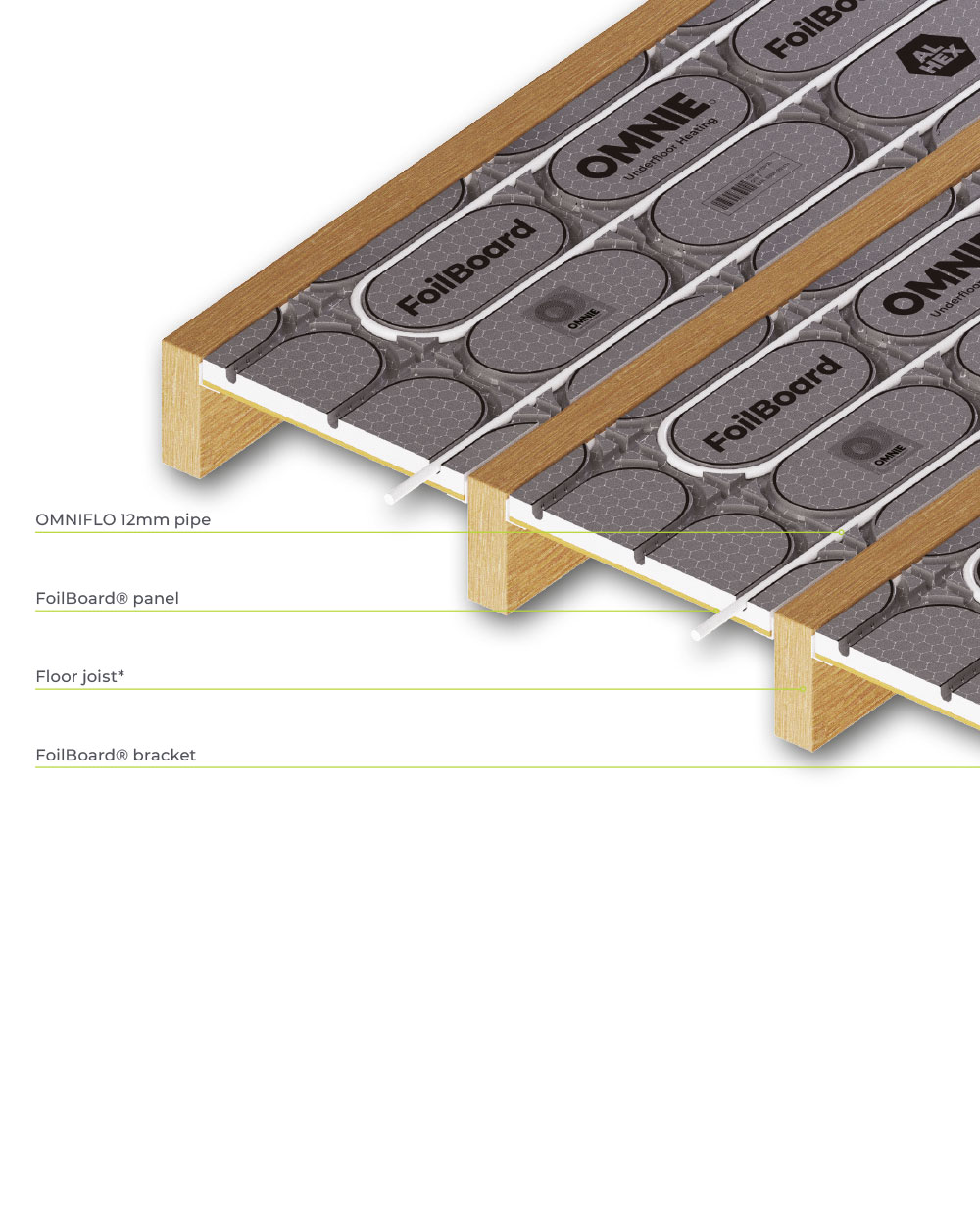

Our FoilBoard system provides assured performance in timber suspended floors. The FoilBoard panels are manufactured from XPS insulation, with a 6mm pre-bonded high-density wood layer and a pre-bonded soft temper aluminium. As no thick rigid plates are used the panels can be easily trimmed on site.

The FoilBoard panels are laid between joists and can be supported by OMNIE L brackets or battens. This ensures that the system is in direct contact with the floor deck, maximising the transfer of heat from pipe to the deck. Once the panels are in place the pipe is pressed into the channels piercing the foil diffuser and fitted into notches in the joists as it passes between inter joist spaces.

How to install OMNIE FoilBoard

Specifications

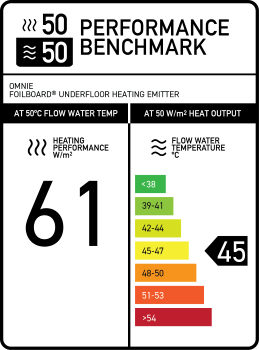

Heat outputs

For more information on our performance benchmark please click here.

Heat outputs are dependent on the water temperature, floor construction, system dimensioning, floor finish & design conditions. Contact us for advice and information.

Based on 12mm PE-RT pipe at 133mm centres with 18mm chipboard laid under 15mm wood, carpet and underlay, and tiles. Air Temperature = 20°C. 0.15 m²K/W = 1.5 TOG.

| Floor Finish | Flow and Return Water Temperature (˚C) | |||

|

55/48 |

50/43 |

45/38 |

40/33 |

|

|

Tile Finish (0.01m²K/W) |

85 W/m² |

72 W/m² |

58 W/m² |

44 W/m² |

|

15mm Wood Finish (0.1m²K/W) |

68 W/m² |

57 W/m² |

46 W/m² |

35 W/m² |

|

Direct 18mm Structural Wood Finish (0.13m²K/W) |

92 W/m² |

77 W/m² |

63 W/m² |

48 W/m² |

|

Carpet & Underlay (0.15 m²K/W) |

62 W/m² |

52 W/m² |

42 W/m² |

32 W/m² |

How to specify

We recommend that you order our products directly through us so that you obtain the most appropriate system and performance specification for the project.

To get a quote please click here or call 01392 36 36 05

Information on product performance and suitability can be supplied by our projects team who are available via our technical support line – 01392 36 36 05. Alternatively please speak to your local business development manager or area sales manager who will happily talk you through our product range and also arrange for samples as you may require.

If you need information on complex constructions such as those with specific acoustic properties, or you have a specialist requirement that is not covered by our standard product range please call 01392 36 36 05.

Detailed installation instructions and a layout plan of the system is included in every system that gets dispatched to site. If you require any additional information at the time of installation we recommend you visit our resources library on our website.